Page 1 of 2

Machined Greeblies

Posted: Thu Nov 13, 2025 1:18 am

by jeanluc83

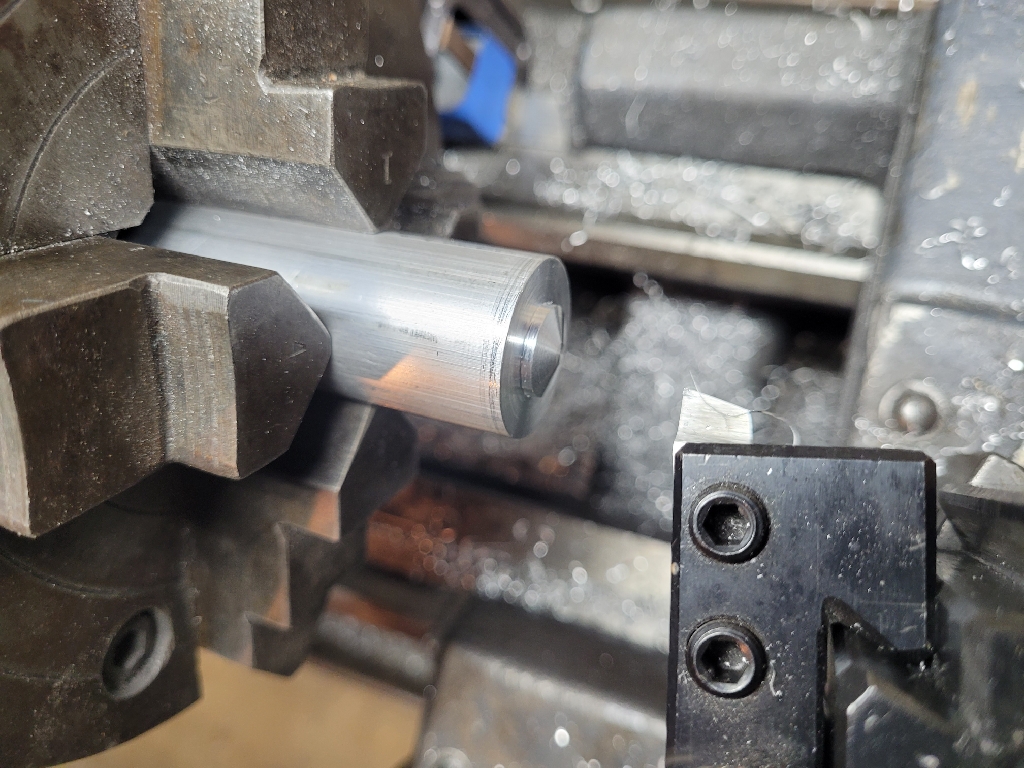

I’m planning on machining all of the greeblies for my R2. 3D printed details are okay but machined aluminum parts are so much nicer. All of the machining will be done manually so some of the details will be challenging but should be fun. First up is the shoulder buttons since they are the simplest.

- 20251108_163937_resize_1.jpg (557.13 KiB) Viewed 657 times

I started with a piece of 1” diameter 6061 aluminum. The profile was turned in the lathe. I then rough cut it to length using a band saw and faced the back. The center hole was tapped 8-32 for mounting.

- 20251111_143309_resize_5.jpg (542.78 KiB) Viewed 657 times

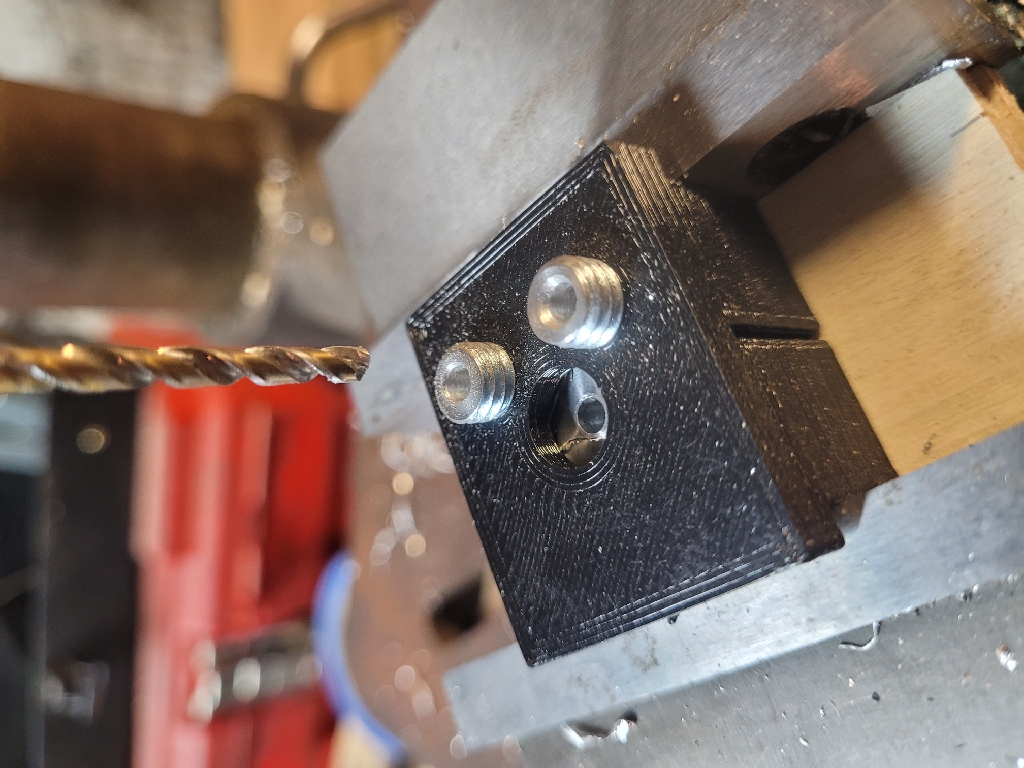

The two holes near the outer edge were a little tricky. I don’t have a vertical milling machine and hand layout is not nearly accurate enough for this so I had to get creative. I ended up making a 3D printed drill fixture. The two metal parts are drill bushings made out of bolt cutoffs from the scrap bin. They were pressed into the fixture to keep the drill from eating up the plastic. The setup worked surprisingly well.

- 20251111_145810_resize_86.jpg (472.48 KiB) Viewed 657 times

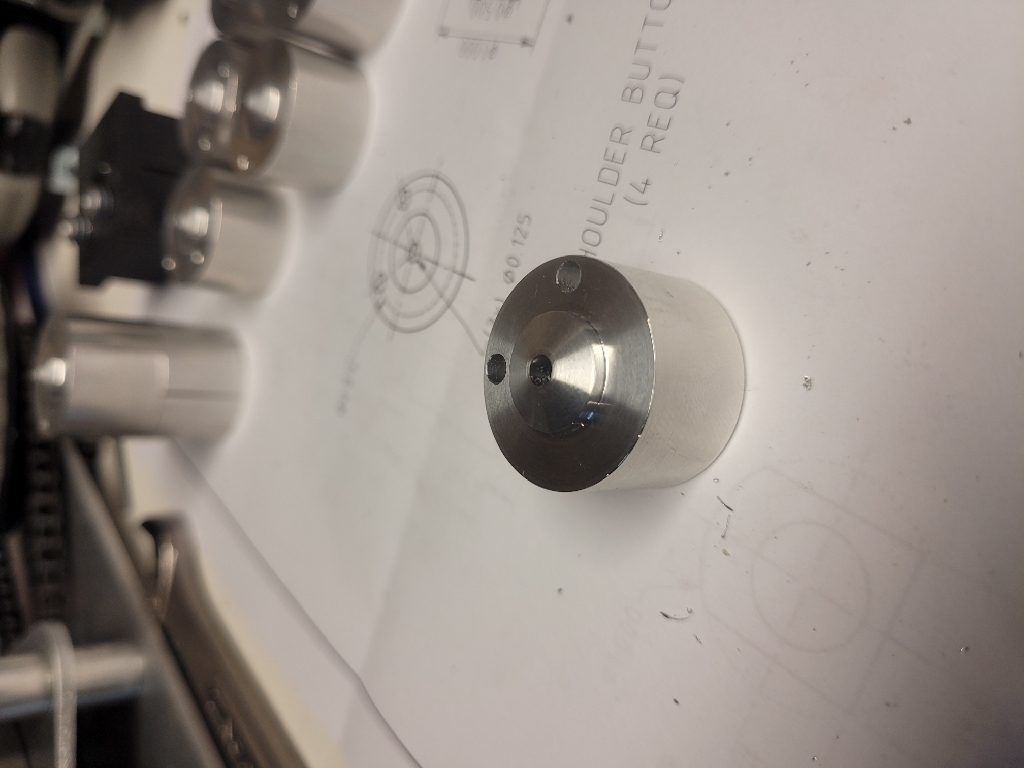

Overall I’m really happy with the way the buttons came out.

Re: Machined Greeblies

Posted: Thu Nov 13, 2025 1:22 am

by jeanluc83

A couple of close-ups.

- 20251111_145819_resize_62.jpg (357.14 KiB) Viewed 655 times

- 20251111_145856_resize_44.jpg (381.7 KiB) Viewed 655 times

Next up will be the shoulder hydraulics. They are also pretty simple but there are a couple of the details that may be a little challenging to reproduce.

Re: Machined Greeblies

Posted: Sat Nov 15, 2025 1:25 pm

by Marc ph

Those are amazing

Re: Machined Greeblies

Posted: Sun Nov 16, 2025 6:38 pm

by jeanluc83

Marc ph wrote: Sat Nov 15, 2025 1:25 pm

Those are amazing

Thanks!

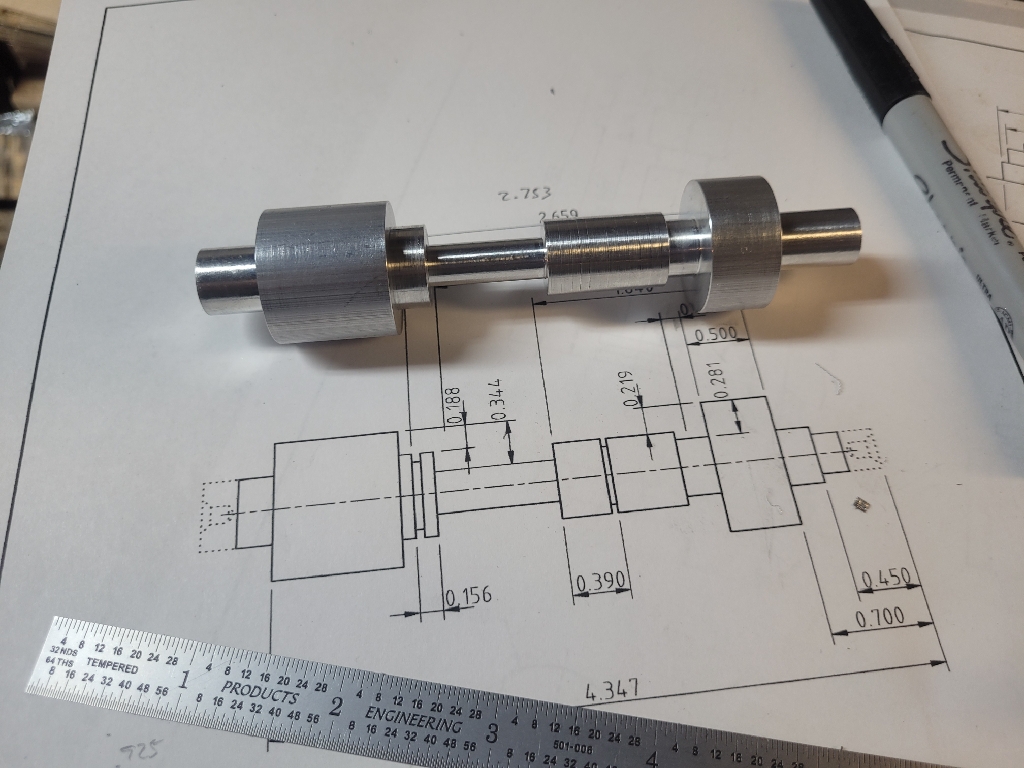

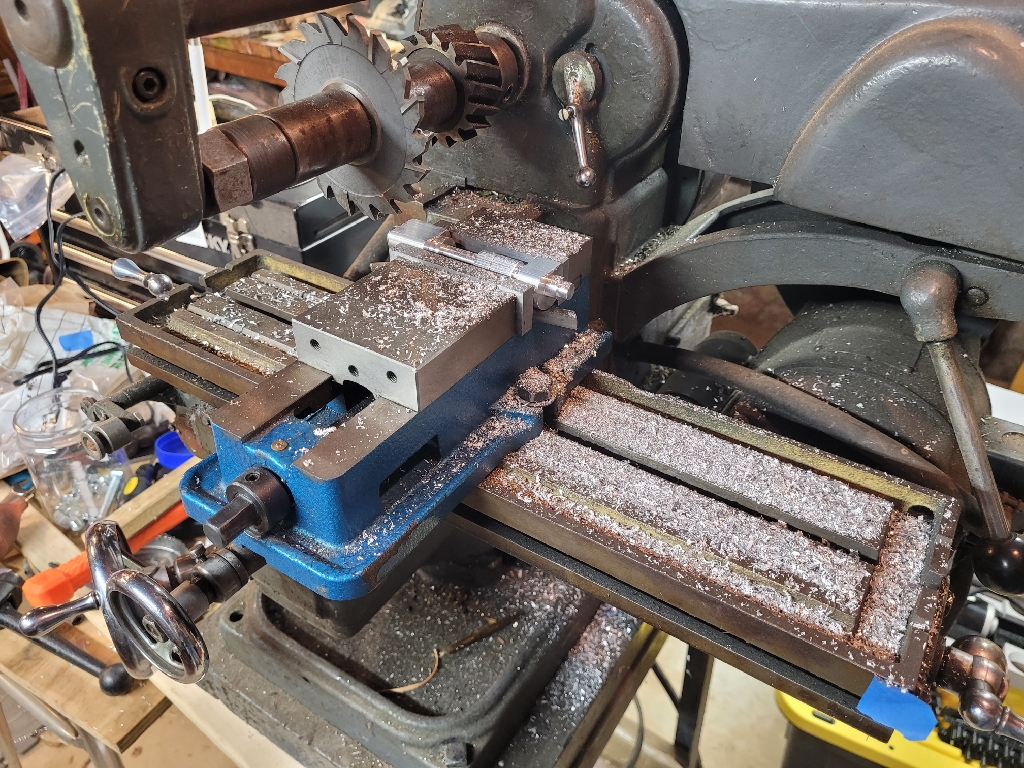

I've started tooling up for the shoulder cylinders. I don't have a straight knurling tool so I'm making the knurls using my lathe like a shaper. A tool bit was ground to 90 degrees which is fed longitudinally using the lathe carriage advancing the tool bit until final depth. The spacing of the knurls was set using evenly spaced marks around the chuck and a pointer. The knurls on the test piece turned out good but the process is a bit slow. I'm sure it will be a bit faster once I get into a rhythm.

- 20251115_173447_resize_74.jpg (675.92 KiB) Viewed 637 times

- 20251115_173452_resize_44.jpg (539.12 KiB) Viewed 637 times

- 20251115_173542_resize_20.jpg (528.88 KiB) Viewed 637 times

Re: Machined Greeblies

Posted: Sun Nov 16, 2025 8:54 pm

by AFR0J3D1

Be careful you might be the greeblies guy before long. These look very cool.

Re: Machined Greeblies

Posted: Mon Nov 17, 2025 11:44 am

by jeanluc83

AFR0J3D1 wrote: Sun Nov 16, 2025 8:54 pm

Be careful you might be the greeblies guy before long. These look very cool.

That is not a bad idea but I’m only making a set for my own use, at least for right now. I may make some more in the future to offset the price of the parts I can’t make but I don’t think I could ever compete with CNC machined parts runs.

Re: Machined Greeblies

Posted: Tue Nov 18, 2025 12:17 am

by AFR0J3D1

well, we are here for the ride keep up the good work.

Re: Machined Greeblies

Posted: Thu Nov 20, 2025 1:25 am

by jeanluc83

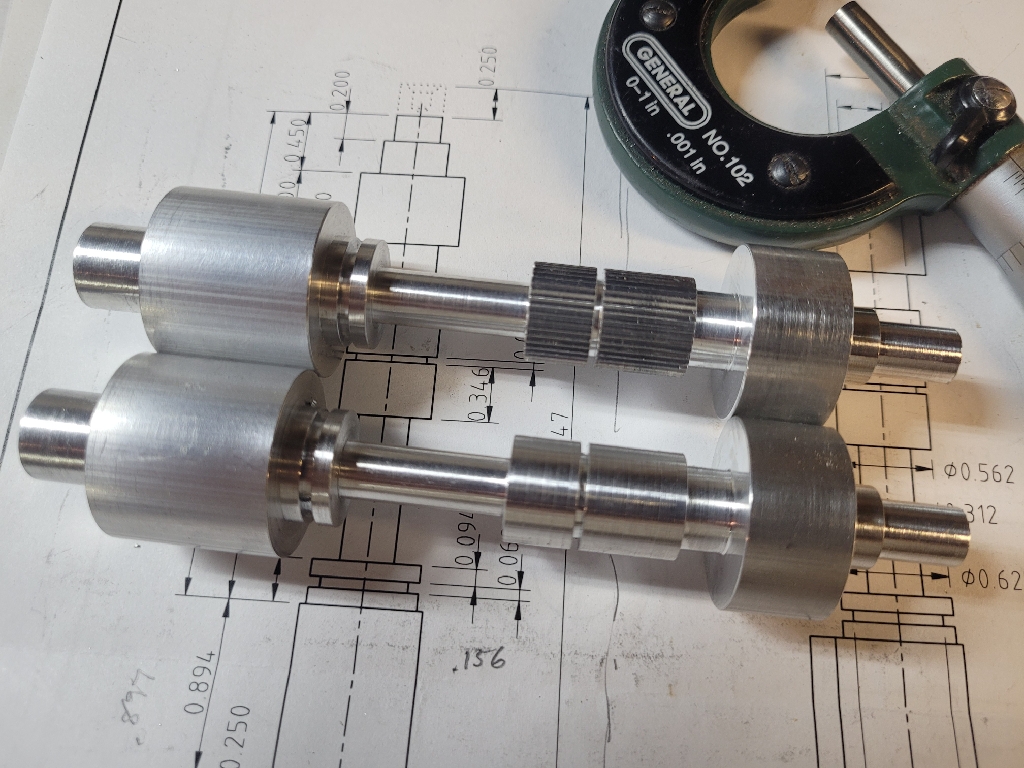

I'm making progress but I'm down to 2. I've made some stupid mistakes but it happens. I'll get there in the end.

- 20251119_195223_resize_94.jpg (432.87 KiB) Viewed 548 times

Re: Machined Greeblies

Posted: Sun Nov 23, 2025 1:31 am

by jeanluc83

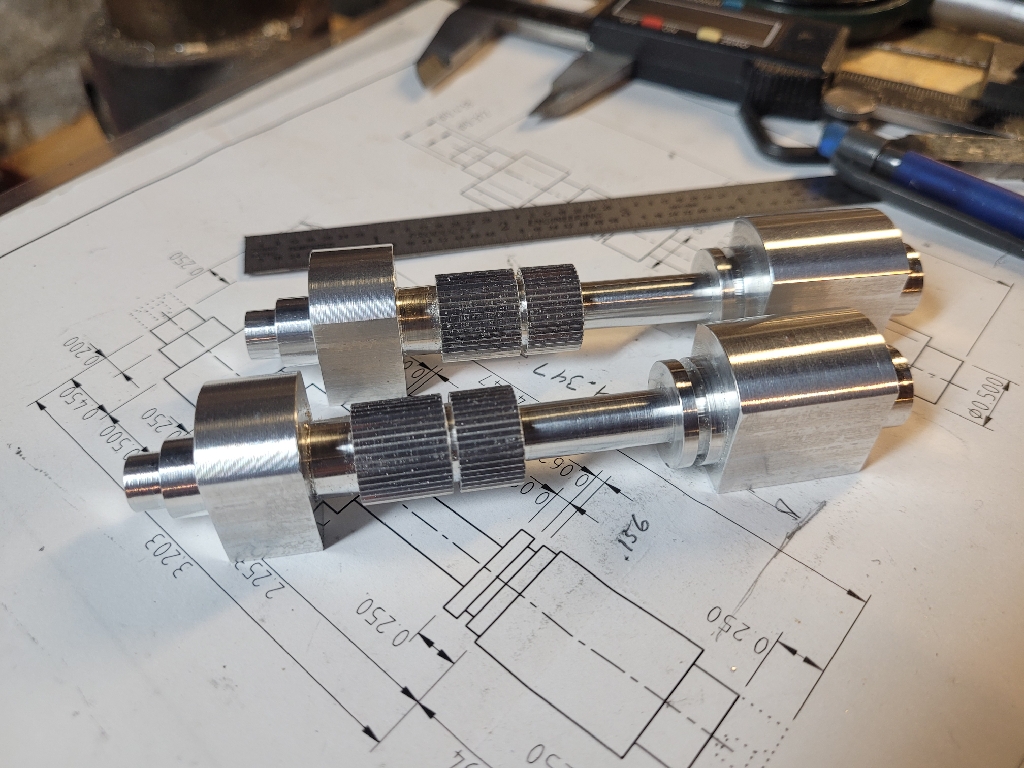

More progress. I'm really happy with how these are turning out.

- 20251122_185624_resize_3.jpg (532.28 KiB) Viewed 511 times

Re: Machined Greeblies

Posted: Tue Nov 25, 2025 11:17 pm

by jeanluc83

The shoulder hydraulics are nearly done. It took me a bit longer than expected but I'm happy with the result. All that is left is to sand out the milling marks and drill and tap the mounting holes.

- 20251125_161315_resize_60.jpg (528.51 KiB) Viewed 479 times

- 20251124_163353_resize_45.jpg (734.7 KiB) Viewed 479 times